Understanding Fly Lines

By Bill Carnazzo

This article deals with the basics of fly lines and will not delve into specialized lines, such as those designed for two-handed rods or specific salt water and/or tropical applications. Once one has a grasp of the basics, it will become much easier to digest the bounty of information to be found on-line covering all manner of lines, floating and sinking.

For a good overview of the dizzying array of options available, it can be educational to browse websites that feature a wide array of lines, such as Rio here: https://farbank.com/collections/rio-freshwater-fly-lines

Or experiment with Rio’s fresh water fly line selector tool here: https://farbank.com/pages/search?q=line+selector

Choosing the Right Fly Line

Selecting the right line for your fly fishing application and a particular rod is extremely important.

In the sport of Fly Fishing, the line is a very important component in the delivery system that propels the fly to the fish. It will also play a large part in whether the fish actually takes the fly or not. Often it is a key factor in whether the fish will be landed or lost. By definition the line also determines whether a person is “fly fishing” or doing some other kind of fishing. In the case of “fly fishing”, the line provides the weight that loads the rod and extends that kinetic energy to the target. In that way, a lure that is too lightweight to generate enough energy is taken along for the ride. A fly line can be an elongated float or an elongated sinker. It can also be any color including clear. Have you ever wondered how a fly line is made?

In the sport of Fly Fishing, the line is a very important component in the delivery system that propels the fly to the fish. It will also play a large part in whether the fish actually takes the fly or not. Often it is a key factor in whether the fish will be landed or lost. By definition the line also determines whether a person is “fly fishing” or doing some other kind of fishing. In the case of “fly fishing”, the line provides the weight that loads the rod and extends that kinetic energy to the target. In that way, a lure that is too lightweight to generate enough energy is taken along for the ride. A fly line can be an elongated float or an elongated sinker. It can also be any color including clear. Have you ever wondered how a fly line is made?

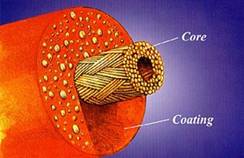

| The key parts that determine the performance of a fly line are: The Core The Coating Taper Design Line Weight |

Every line can be dissected into two parts: Core and Coating. It’s the modification of these parts that allow fly lines to be designed with specific performance characteristics — castability, shootability, and durability — to meet the demands of most fly fishing situations.

The Core — It’s t he core of the fly line that determines its tensile strength, as well as how much it stretches. It also helps determine how stiff the line will be.

he core of the fly line that determines its tensile strength, as well as how much it stretches. It also helps determine how stiff the line will be.

Strength — all line cores are built to be much stronger than the heaviest tippets that are likely to be used with them.

For example: a 2 or 3 weight line will normally break at about 20 lbs.; a heavy saltwater line core may test over 40lbs.

Stretch — it’s important that a fly line core have the right amount of stretch. Not enough stretch and the line may develop ‘memory’ problems. Too much stretch and the fly line becomes ‘mushy’ and difficult to control.

Stiffness — the core also plays an important part in the stiffness of the line. Lines intended for tropical fishing are designed to withstand high heat extremes and maintain their inherent stiffness. Lines developed for use in more temperate climates are made with cores that are less stiff, reducing the problem of line memory that occurs when stiff lines meet cool conditions.

The Coating — How a line coating is formulated, and how it is applied to the line’s core, determines the rest of the line’s performance characteristics.

One of the most basic and important functions of the line coating is to provide the casting weight needed to load the fly rod. Precise weight standards are set by the fishing tackle industry; the right amount of coating must be applied to each line in order to meet this standard.

It is primarily the density of the line’s coating that determines whether the line will float or sink. Floating lines have special micro balloons mixed into their coatings that allow for accurate control of line density. Lines that are lighter than water will float. But if too many micro balloons are added, the thicker diameter of the line will make it more wind resi

It is primarily the density of the line’s coating that determines whether the line will float or sink. Floating lines have special micro balloons mixed into their coatings that allow for accurate control of line density. Lines that are lighter than water will float. But if too many micro balloons are added, the thicker diameter of the line will make it more wind resi stant, making it harder to cast. The optimum density is one that strikes a balance between the floatability and castability of the line. Newer floating fly lines also employ hydrophobic agents to make their coating water-resistant. These lines actually repel water, making them float higher than other lines of the same density.

stant, making it harder to cast. The optimum density is one that strikes a balance between the floatability and castability of the line. Newer floating fly lines also employ hydrophobic agents to make their coating water-resistant. These lines actually repel water, making them float higher than other lines of the same density.

Conversely, sinking lines incorporate a high-density material into their coatings to make them heavier than water. Although very expensive, powdered tungsten is most often used because it is denser and more environmentally friendly than lead. By precisely controlling the formulation of how much metal powder is added to the fly line coating, sink rates from as little as 1.25 inches per second to as much as 10 inches per second can be achieved.

Fly line coatings also contain the pigments, which determine the visibility of the fly line to both the angler and the fish.

Taper design: The Key to Casting Performance

The fly line’s shape or taper determines how energy is transmitted and dissipated during casting. By varying the lengths and diameters of the various parts of the line, specific performance attributes can be accentuated.

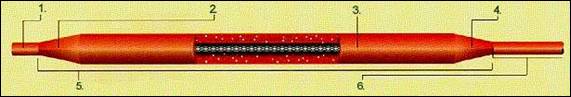

The parts of the taper are:

1. Tip: a short 6-12 inch level section where you attach your leader. This section’s role is to protect the line’s taper. Since many anglers cut off a small part of fly line when they change leaders, the level tip allows these changes without shortening the front taper and altering the way the line casts.

2. Front Taper: this is the section of the line that determines how delicately or powerfully the fly is delivered. Typically, 4-8 feet long, it decreases in diameter from the Belly section to the Tip. This graduation of the line’s mass (weight) determines its ability to transfer you casting energy.

3. Belly: because it is the widest diameter and longest length, this section is where most of the weight of a line is located and, consequently, where your casting energy is carried.

4. Rear Taper: decreasing in diameter from the thicker belly section to the much smaller diameter running line section, the rear taper creates the transition so important to casting smoothness.

5. Head: this term is used to describe the combination of front taper, belly and rear taper

6. Running Line: this section exists primarily to make distance casting easier.

Since a Double Taper (DT) line is essentially a long belly with tapers at both ends, there is no running line by definition. This large diameter belly line does not shoot through the rod guides easily. A smaller diameter, lighter weight line creates less friction. The running line portion of Weight Forward (WF) and Shooting Taper (ST) configuration fills this role. The Head is extended through the tip of the rod. The rod is loaded with the weight of the Head. Further extension of the fly line is accomplished by stripping line from the reel and then ‘shooting’ it through the guides.

Taper Types

When choosing a line for the fishing that you plan to do, there are several taper options to consider: Level (L), Weight Forward (WF), Double Taper (DT), Shooting Taper (ST). Specialty Tapers are variations of Weight Forward and Double Tapers. Weight Forward configurations are most popular for a variety of reasons and have more variations. Lets look at the performance you’ll get from each option.

Level (L)

With no taper design at all, this line has in most situations, very low performance characteristics. It transfers energy very erratically and is hard to control while casting. The best function of level lines is in the form of fine diameter Shooting Lines or in inexpensive sinking lines to be cut up for tips for custom lines.

Weight Forward (WF)

The Weight Forward design allows you to make short to long casts (20-80 feet) with normal size flies. Most anglers find that Weight Forward lines are versatile and work well over a wide range of conditions. This type of design comes in many configurations to meet specialized situations or perceived presentational improvements. Any line whether floating or sinking which has a Head and Running Line section which are seamlessly joined can be termed a Weight Forward fly line. Rocket Tapers, Bass Bug Tapers, Saltwater Tapers, Steelhead Tapers, Triangle Tapers and Teeny Tapers are all weight Forward Fly Lines.

Double Taper (DT)

A reversible fly line with an identical taper at both ends. Easy to mend and roll cast. Most useful on moving water. This style of line is designed for short to medium casts (20-50 feet) with normal size flies. Floating lines are popular in this configuration.

Shooting Taper

Also called Shooting Head fly lines consist of two separate lines which are joined with a loop to loop junction. The front portion (or head) is the same configuration as the head (first 30′) of a Weight Forward fly line. The second portion consists of a fine diameter Running Line. Its purpose is to cut friction in both the rod guides and in the water.

Triangle Taper

Designed by Lee Wulff, the Triangle Taper configuration is a continuous forward taper in the head of the line. Head length can vary from 27 to 80 feet depending on the line weight and proposed application. Many anglers believe these designs provide the most efficient transfer of casting energy over a wide range of distances. As the loop unrolls, heavier line is constantly turning over lighter line.

Teeny Taper

A radical Weight Forward fly line which was pioneered by Jim Teeny. It lacks a front taper on the fast sinking head and has a finer than normal running line similar to a shooting taper configuration. The sole purpose of this line is getting deep in the water quickly. Several manufacturers have copied this line.

Standard Line Weights – Grain weights are for the first 30′ of the line.

AFTMA (the former American Fishing Tackle Manufacturers Association- now the ASA- American Sportfishing Association) Fly Line Standards were developed to help fly fishing tackle manufacturers create a system that would match fly line weight to fly rod performance. Cortland Line Company’s Leon Chandler was instrumental in initiating and completing the project. In theory this would standardize fly tackle manufacturing across the industry and enable fly fishers to select and balance their equipment for optimum performance.

The system uses the weight in grains (a very small weight measure) of the first 30 feet of fly line as a standard. The table below shows fly line weight designations and their grain weight. The system also established a tolerance level that is acceptable. (Copied from Cortland Line Company’s web site.)

| Number Designation | Standard Weight | Margin For Error |

| 1-Weight | 60 | 54-66 |

| 2-Weight | 80 | 74-86 |

| 3-Weight | 100 | 94-106 |

| 4-Weight | 120 | 114-126 |

| 5-Weight | 140 | 134-146 |

| 6-Weight | 160 | 152-168 |

| 7-Weight | 185 | 177-193 |

| 8-Weight | 210 | 202-218 |

| 9-Weight | 240 | 230-250 |

| 10-Weight | 280 | 270-290 |

| 11-Weight | 330 | 318-342 |

| 12-Weight | 380 | 368-392 |

| 13-Weight | 450 | |

| 14-Weight | 500 | |

| 15-Weight | 550 |